Allison Hybrid High-Voltage Qualified Instructor-Led Course

This 8-hour instructor-led training transforms technical curiosity into confident competence, anchored by a Safety First approach. Participants are introduced to the Allison EP40 Hybrid System, building a strong foundation in electrically safe work practices, system awareness, and service-critical procedures essential for modern hybrid transit maintenance.

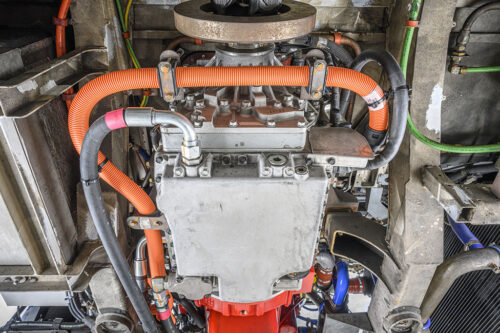

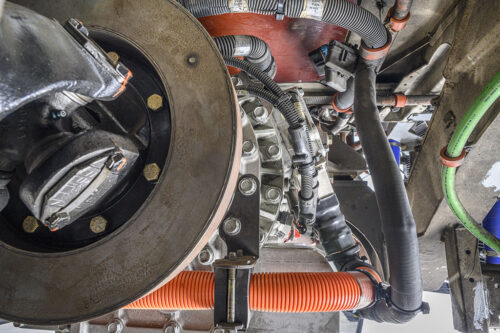

Technicians will learn how to recognize high-voltage hazards, properly inspect and wear Personal Protective Equipment (PPE), and verify electrically safe work conditions using real-world procedures such as Lockout/Tagout (LOTO) and disconnect verification. Emphasis is placed on hands-on familiarization with the EV DRIVE™, Dual Power Inverter Module (DPIM), and rooftop-mounted Energy Storage System (ESS), the heart of the hybrid drivetrain.

This is more than an orientation. It’s a safety-centered and systems-focused experience, where hybrid diagnostics, motor insulation testing, and high-voltage circuit checks are introduced to support technicians pursuing high-voltage qualification and long-term maintenance excellence.

Core Safety Topics Covered:

- Lockout/Tagout (LOTO) and electrical disconnect verification

- High Voltage Interlock Loop (HVIL) theory and service safety

- PPE selection, inspection, and use for HV systems

- ESS voltage and current ranges with hazard precautions

- DPIM hazard labeling and safe maintenance techniques

- Contact Release, protection boundaries, and visual hazard cues

- Safety-Focused Training

Recognize high-voltage components, use PPE correctly, and follow standard procedures to create an electrically safe work condition. - Hybrid System Familiarization

Gain practical understanding of the EV DRIVE™, DPIM, and ESS—including torque transfer, energy flow, cooling circuits, and regenerative braking. - Diagnostics & Troubleshooting Readiness

Learn the basics of reading DTCs, performing insulation resistance checks, and understanding motor test results. This creates a foundation for more advanced high-voltage diagnostics. - Preventive Maintenance Essentials

Inspect and service rooftop ESS filters, check transmission fluid with the Pushbutton Shift Selector, and verify proper cooling of the DPIM. - Hands-On Confidence

Apply your knowledge in guided exercises on a real transit bus, reinforcing concepts and building familiarity with hybrid-specific components.

In-person course duration: 8 hours over 1 day

In this course, participants will:

- Identify hybrid system components and high-voltage zones using actual bus equipment.

- Explain how the High Voltage Interlock Loop (HVIL) protects technicians and how to test for proper function.

- Demonstrate proper use of rubber-insulating gloves, perform PPE inspections, and set up protection boundaries.

- Perform basic insulation and motor tests and interpret test outputs during hybrid fault conditions.

- Use the Pushbutton Shift Selector and Allison DOC™ to access and interpret DTCs.

- Practice ESS air filter inspection, DPIM cooling line checks, and system-level maintenance readiness.

- High-Voltage Awareness Level 1 (recommended)

- Contact Release (recommended)

- Digital Volt-Ohm Meter (recommended)

- High-Voltage Awareness Level 2 (recommended)

- Basic understanding of heavy-duty vehicle systems

- Rooftop safety and fall protection certification

Curriculum supports HV qualification training pathways and reinforces the practices required under OSHA 1910 and NFPA 70E safety standards.

- Mechanics new to hybrid or electric transit systems

- Journeyman technicians preparing for HV qualification

- Maintenance managers seeking team readiness for hybrid fleet support